emile666 / stc1000_stm8 Goto Github PK

View Code? Open in Web Editor NEWSTC1000p for the STM8 microcontroller (HW version WR-032)

License: GNU General Public License v3.0

STC1000p for the STM8 microcontroller (HW version WR-032)

License: GNU General Public License v3.0

Hi,

I am developing a PID temperature controller for controlling temperature using a peltier element and an H-bridge.

The H-bridge is controlled using 2 PWM signals. Heating is faster than cooling, so 2 PID controllers are needed because the parameters are different. I used your PID code, but Kc is never set in the software?

Furthermore,

can you give me a tip how I can heat from 10 to 15 degrees and then stay at 15 degrees and the temperature does not rise due to room temperature

Currently, when in PID-mode, there's no way to manually fix the pid-output to a certain value. This is handy for testing the control-loop and when doing a step-response.

In PID output display mode (PWR button pressed twice), decimal dot is not showing. I think it would be less confusing if it showed.

on 103f3 programmed with STVD can't enter menu. S button switches between some temps. S long press leads to Off. Another S long press leads to restart. If I quickly press up I enter menu (Pr1-...Pr5- Set), but S press leads to main screen and so on. Help! :)

Hello,

First of all thank you for your work, especially for the inversion of electronic diagrams

I would like to use an esp32, to monitor my fermentation chamber. I already have an esp32 with a ds18b20 sensor which sends me the temperature every 10sec.

I want to know the status of the cooling and heating relays. So I think there are two ways to handle it:

1. Use pins 5 and 6 which trigger the transistors of the relays?

2. Use the LED signal on the front panel, but I don't know where it is. I'm assuming there is some sort of multiplexing for display management (I2c?)? Can you describe the input of the 7-segment display DIS1?

What do you think is the best way to manage it?

If I use the first choice I guess I can't pin this to esp32, the best way is to use a transistor or divider bridge (5v-> 3.3v)

Do you have the reference of the temperature sensor? Where is it on the diagram?

Finally, do you have a quick explanation of what it is: SWIM_4, NTC1, NTC2, CC1, CC2, CC3, CC4, S3

SWIM_S4 is some kind of debugging channel? but why is it connected to the screen?

CC1 and CC2 is an I2c bus to control the display?

NTC1, NTC2 is the temperature sensor? Why is it also wired to the screen?

Thank you

Could you please implement a communication protocol like Mats did on the pic version to read/write temperature as well as settings with an external controller? I plan to attach an IoT controller for remote control purposes, logging as well as having a graphical UI.

I have received STC-1000 WR-032 V2 with 74HC164 chip on front board and no-label chip for uC , still assume that it is STM8 based .

SWIM interface has signals SIG , RST , VDD, GND , GND1 so probably it is uC STM8

Please is there any schematics or info on this revision ?

I have two STCs with the STM8S003F3, and I upgraded them before testing them. Now, I notice that they are getting a lot warmer than other STCs I have (the one matsstaff fiddled with). I insulated my probe and stuck it in the STC case, and it is measuring~50 C. Is this normal? Are these STCs like this regardless of the firmware? I feel reluctant to enclosing this in a box and having it on for weeks..

The probe is not calibrated, but i can feel the heat coming of the STC.

There is no load on the relays.

I have two probes connected to the STC, and the ambient temperature is (uncalibrated) ~20 C.

Update: Inside the case, close to the little transformer, I now read 72 C. It's been running (still without load on the relays) for four hours.

I am new to github and have no idea how I should contact you, so this is how i chose to do it. I am sorry if it is the wrong way.

Hi,

thanks a lot for your code... however I have flashed it and I get OFF all the time. I have tried to flash it several time but always the same error. Could it be something with the software?

thanks

Hi, I had problems programming a newer version of the STC-1000. Solution given at https://owenduffy.net/blog/?p=18048 .

I did not try, but it may have been possible to program the original unlabelled chip once C2 was fitted. By the time I had removed the front panel board, I might as well replace the MCU.

You are welcome to use any of the content for this repo or associated wiki.

Owen

2020/07/12: I can add that it was not possible to program the chip on a new unit even after fitting C1 and C2... the unmarked chip may have been an OTP.

PID output is stuck at 0. In thermostat mode, heating gets turned on. It worked fine the last time I used it, and no hardware or setting change was made. Any ideas? Thanks!

UPDATE:

After I manually turned the heating on and the temperature increased, PID kicked in.

Is possible to use the PID mode just for the heating output (a heating cable) and standard bang-bang mode for the cooling device (a peltier cell that wouldn't work in PID mode) ?

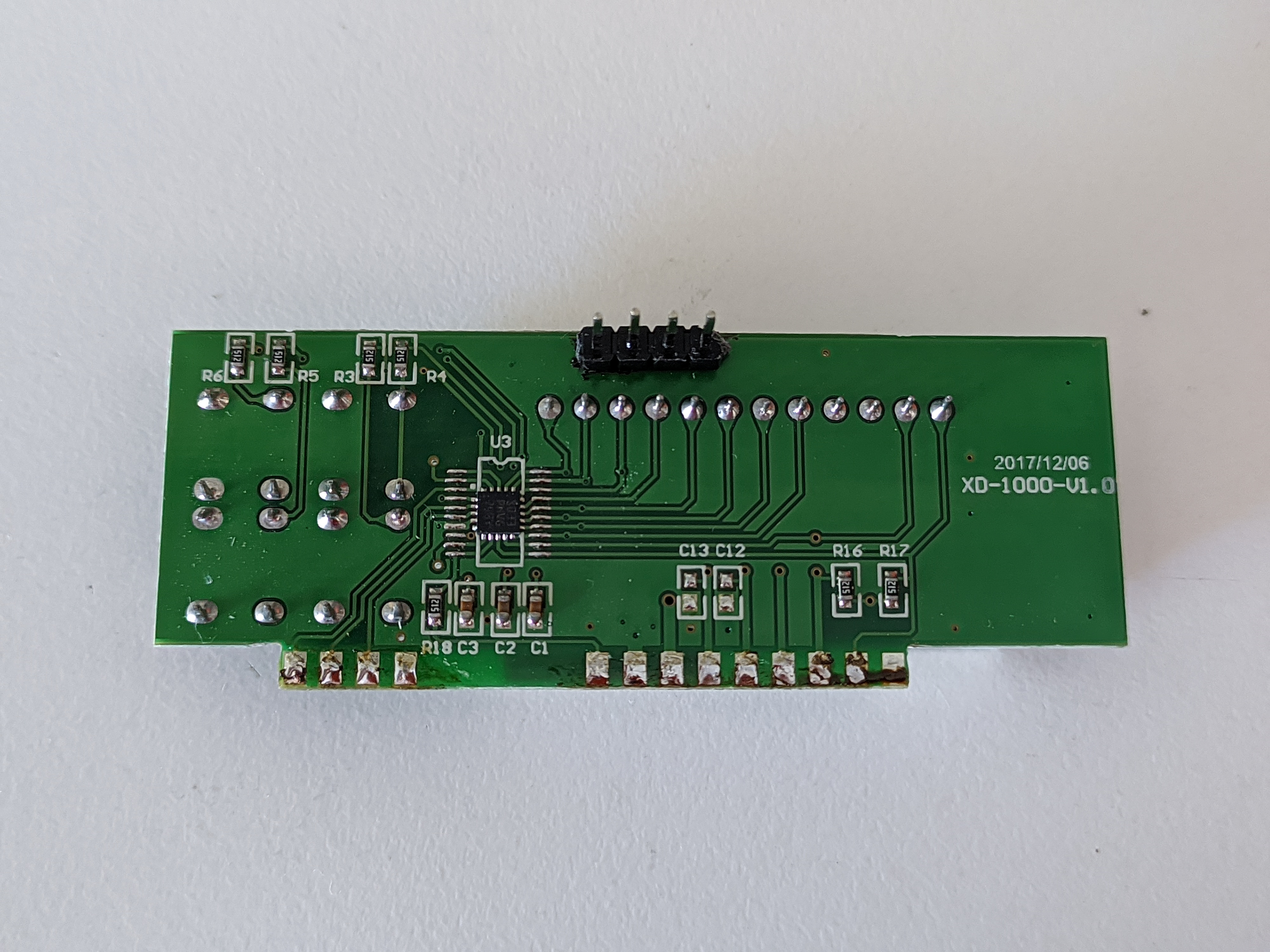

I've got this STC-1000 that has the same box as emile (like the WR-032-v1), but has a different PCB name. This one is the XD-1000-v1.0. The backplane looks to be pretty similar to the WR-032 v2 board . The only difference that i was able to find is that this version (compared to the WR-032-v1) uses the UFQFPN20 package of the STM8S003F3, while also having the pads and silkscreen for the TSSOP20 version of the same chip. I'll add some photos of the front-pcb and the power pcb.

The problem i'm experimenting is that temperatures do not get read properly, in the sense that both numbers (NTC1 and NTC2) start at 25cº, but the NTC1 starts to raise up and the NTC2 starts to go down, until they stabilize at 40cº and 1cº respectively. I only plan to use this STC with one temperature probe, and no SSR or any extra mod.

I've tried using IAR to reduce or even disable the number of averaged measurments, but it seems to have no change at all.

What else can i try to fix this problem??

It seems that using the menu to set SP in th mode does does not actually set the SP, though it stores it.

The only way I found to fully set a SP is to make a profile with SP0 what I desire, and dh0=0, and it immediately expires and passes the SP into the th mode, and the controller works as it should.

I thought from the docco that I could ignore prfofiles and simply set th run mode, ts=0 to disable PID, and SP etc for the working 'single stage' operation.

Owen

Hi,

could you write a firmware with which you can use the heating output to switch on the 230V inverter ?

best regards

Marcus

is there any way to use the OVBSC firmware on this device.

I found out I had this device and would like to use it to control a pump.

I have a 3V system, and just want to use the STC as a timer to start the brew day the night before, then heat the HLT, then start mash in.

For example:

Set profile 1 - 10 C for 8 hours (delay start for 8 hours), profile 2 - 75C for 2 hours (heat to 75C), start pump for 5 mins (transfer hlt to mash tun).

I've done basic php programming but never programmed these types of devices. Would this be hard to program?

Your system doesn't say anything about controlling a pump?

Any feedback or ideas would be great thanks. (even if its just that I need to get the right STC-1000).

Good afternoon,

I came across your github and I see that you are very experienced in realizing PID controllers.

I am working on creating a PID controller for controlling the water temperature using a peltier, H-bridge and PID.

The PID for heating has been tuned using your document PID_Controller_Calculus.

I have also tried this with cooling, but this does not work at all. Can you help me to tune the PID for cooling.

I received STC-1000 WR-032 V3.

It is very different from others.

LED display (no identification ) looks the same, but only has 7 pins.

Only one 16-pin mc (no identification ) on front board ( behind LCD).

SWIM interface has SIG , RST , VDD, GND , GND1 (may be stm8?)

I checked it witn a St-link v2 - "Cannot communicate with the target"

(Communication features - SIG & RST pins connected to the same mc pins with 2 & 3 (left to right) pins of LED)

Controller type - do you have any ideas?

A declarative, efficient, and flexible JavaScript library for building user interfaces.

🖖 Vue.js is a progressive, incrementally-adoptable JavaScript framework for building UI on the web.

TypeScript is a superset of JavaScript that compiles to clean JavaScript output.

An Open Source Machine Learning Framework for Everyone

The Web framework for perfectionists with deadlines.

A PHP framework for web artisans

Bring data to life with SVG, Canvas and HTML. 📊📈🎉

JavaScript (JS) is a lightweight interpreted programming language with first-class functions.

Some thing interesting about web. New door for the world.

A server is a program made to process requests and deliver data to clients.

Machine learning is a way of modeling and interpreting data that allows a piece of software to respond intelligently.

Some thing interesting about visualization, use data art

Some thing interesting about game, make everyone happy.

We are working to build community through open source technology. NB: members must have two-factor auth.

Open source projects and samples from Microsoft.

Google ❤️ Open Source for everyone.

Alibaba Open Source for everyone

Data-Driven Documents codes.

China tencent open source team.